WHAT IS THE ESSENCE OF THE PERFORMAX INTERNATIONAL ENGINEERING DEPARTMENT?

At the forefront of the Australia conversion industry, Performax International are driven to success through Engineering excellence. This being in an industry where small manufacturers provide products into the market which lack the quality and durability of the original OEM product. Performax International goes to great lengths to ensure that this is not the case. Performax hires a highly skilled engineering team who specialise in all areas of automotive design and manufacture and possess the skills to achieve results equal to and better than OEM products. Our ability to achieve this is determined using the following cutting edge engineering technology.

If you have any question on our engineering technology, call us and talk to one of our experienced engineers.

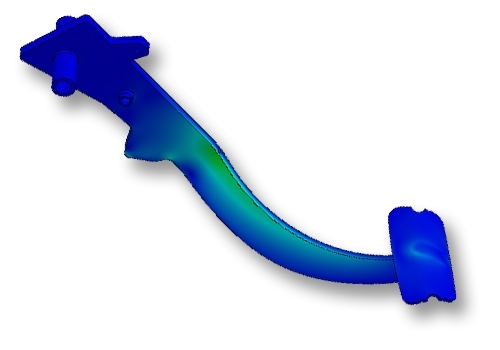

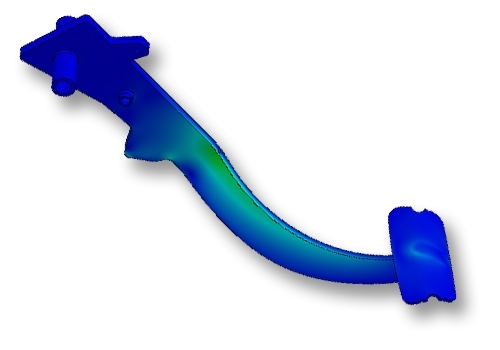

Finite Element Analysis

Engineers perform Finite Element Analysis, a type of stress simulation, on all safety critical parts.

This process applies real world loads to computer models of vehicle components, which allows engineers to identify areas of high stress, and iterate the design to ensure integrity under all operating conditions.

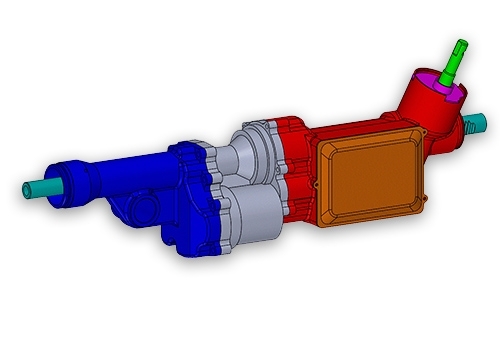

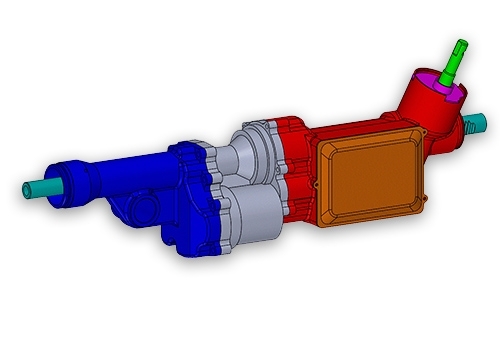

Solidworks

Solidworks is a state-of-the-art Computer Aided Design software package which allows engineers to design parts from scratch using inbuilt tools specific to each manufacturing process.

3D CAD models can then be turned into 2D technical drawings which are released to suppliers for manufacture.

ADR Testing

Performax International is an approved test facility for in-house testing of several Australian Design Rule standards.