OUR EMISSION SYSTEMS GUIDE PROVIDES A DETAILED OVERVIEW OF THE TECHNOLOGY USED TO REDUCE EMISSIONS AND IMPROVE FUEL EFFICIENCY IN OUR VEHICLES

EMISSIONS CONTROL SYSTEM

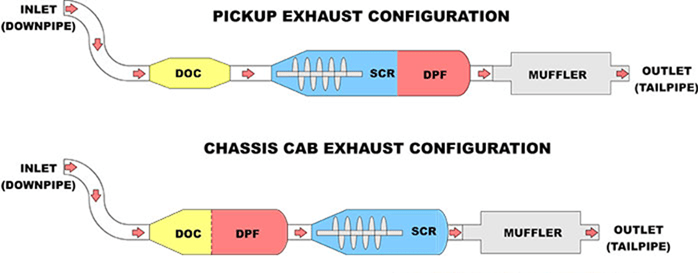

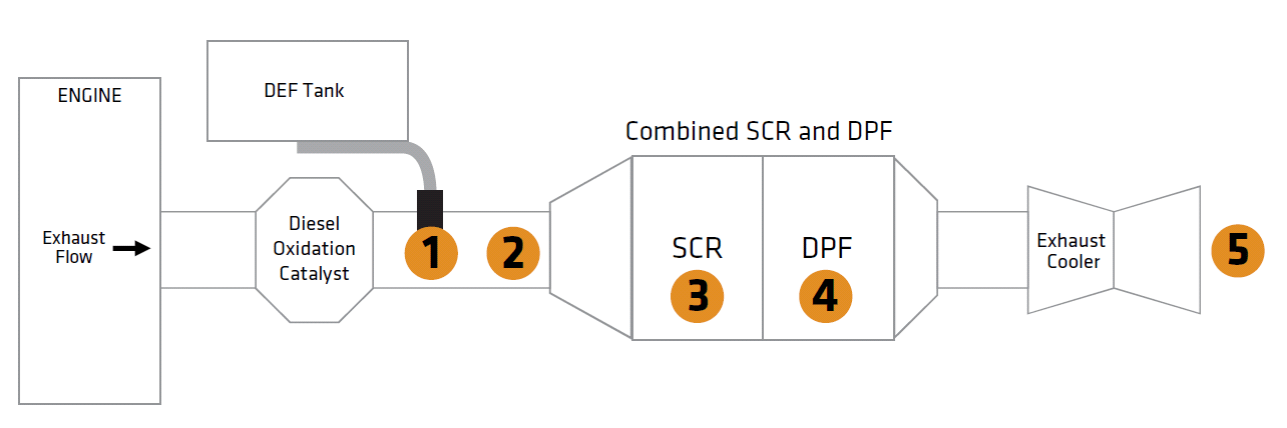

Both The 6.7L Power Stroke diesel and 6.6L Duramax diesel engines meet strict Federally mandated emissions regulations by means of a sophisticated network of inter-laced emission control devices. These include a diesel oxidation catalyst (DOC), diesel particulate filter (DPF), exhaust gas recirculation (EGR) system, and selective catalytic reduction (SCR) process. The SCR system requires the use of diesel exhaust fluid (DEF), a urea based solution that is used to combat NOx emissions by means of a reduction reaction. Various sensors are employed to monitor the condition of the emission control system and control certain processes.

NITROUS OXIDES

Nitrous oxides, typically simplified as NOx, refers to the compounds nitrogen dioxide and nitric acid. These are not to be confused with nitrous oxide. NOx emissions contribute to the development of acid rain and smog. In addition, NOx may worsen preexisting medical conditions such as asthma and bronchitis. Nitrous oxides are produced when combustion occurs in the existence of nitrogen. Such is the case in the combustion of fuel in a diesel engine, as nitrogen gas is a naturally occurring element in atmospheric air.

CARBON MONOXIDE

Carbon monoxide is a colourless, odourless, highly toxic gas produced during the combustion process.

CARBON DIOXIDE

Carbon dioxide is formed as a result of the combustion of various hydrocarbon compounds that make up petroleum based fuels, including diesel. Carbon dioxide is classified as a “greenhouse gas” and CO2 emissions are believed to be a leading contributor of global warming.

DIESEL PARTICULATE MATTER

Diesel particulate matter, often abbreviated DPM, refers to the emittance of soot following the combustion of diesel fuel. The WHO (World Health Organization) has classified diesel particulates as carcinogenic, meaning prolonged exposure may cause cancer. Additional health concerns, including difficulty breathing, have been linked to both short and long exposure to DPM.

EXHAUST GAS RECIRCULATION (EGR)

Exhaust gas recirculation (EGR) is a technique employed to reduce NOx emissions in combustion engines - the process is not specific to diesel engines. On an EGR equipped engine, a metered portion of exhaust gases are re circulated through the intake where they are mixed with the incoming air charge. While the concept may seem counterintuitive, NOx emissions are significantly reduced as a result of;

- Reduced oxygen concentration in the combustion chamber

- Lower combustion temperatures

The flow rate of exhaust gases in the recirculation circuit is controlled by the EGR valve. Its position is directed by the PCM and varies with various parameters, including load, speed, and manifold pressure. As exhaust gases are relatively hot after leaving the combustion chamber, they are cooled prior to recirculation by means of an EGR cooler. The EGR is a heat exchanger that uses engine coolant as a medium to remove heat from the hot exhaust gases. The 2011 - 2014 MY 6.7L Power Stroke is unique in that it has two dedicated cooling circuits. The primary or high temperature cooling circuit is reserved for engine cooling only. A secondary cooling circuit, referred to by Ford as the low temperature circuit, provides cooling to the EGR cooler, charge-air-cooler, transmission cooler, and fuel cooler. For the 2015 MY, the EGR cooler was moved to the high temperature cooling circuit. Do in part to the effectiveness of the SCR system, the 6.7L Power Stroke uses a lower EGR duty cycle than previous generation engines and therefore the system is not inherently problematic.

SELECTIVE CATALYTIC REDUCTION (SCR)

The SCR system is an after-treatment system, since it treats the vehicle’s exhaust after combustion. Here’s how it works:'

- A fine mist of DEF is injected into the exhaust while the engine is running.

- The heat from the exhaust converts the DEF into ammonia.

- When the ammonia, mixed with exhaust gases, reaches the SCR catalyst, the NOx emissions are broken down.

- The Diesel Particulate Filter (DPF) then captures soot to incinerate it during regeneration cycles.

- Water vapor, nitrogen and reduced emissions exit the exhaust system.

DIESEL EXHAUST FLUID (DEF)

Diesel Exhaust Fluid (DEF) is a non-flammable fluid comprised of 33% ammonia-based urea and 67% purified water. DEF is used with diesel engine exhaust systems to reduce the amount of emissions produced by turning Nitrogen Oxide (NOx) into nitrogen and water vapour. DEF technology has a proven track record since it has been used in Europe for years.

DIESEL OXIDATION CATALYST (DOC)

The diesel oxidation catalyst, or DOC, is essentially the diesel equivalent of a gasoline engine’s catalytic converter. As exhaust gases flow through the catalyst, residual hydrocarbons and carbon monoxide gas is converted into carbon dioxide gas and water vapor by means of an oxidation reaction.

DIESEL PARTICULATE FILTER (DPF)

The diesel particulate filter, or DPF, filters particulate matter (soot) from the exhaust stream. Diesel particulate filters can capture up to 100% of particulate emissions and are responsible for the absence of dingy black build up on the tailpipes of modern diesel engines. The PCM constantly monitors DPF loading, or the quantity of particulates captured in the filter. When the DPF is “full”, the filter is cleaned by a process known as regeneration. Under ideal conditions, removal of the DPF for manual cleaning should never be required.

DRIVING RANGE BETWEEN DIESEL EXHAUST FLUID TANK REFILLS

The SCR system uses DEF at a rate of about 1 to 1.25% of the vehicle’s diesel fuel usage. A full tank of DEF provides a driving range of about 5,000 miles (8,000 kilometres). Since DEF usage is directly related to fuel consumption, range will vary depending on driving conditions.

MAINTAINING DIESEL EXHAUST FLUID LEVELS

The electronic on-board warning system will provide a message alerting the driver when the DEF level is around 1000 km remaining range. Additional messages that must be acknowledged alert the driver at the 300 km, LOW and 0 km fluid ranges as the DEF tank gradually empties. The fluid level in the DEF tank must be maintained for the vehicle to run correctly. If the DEF tank is allowed to run empty, the system will alert the driver. If fluid is not added at the next vehicle start, the vehicle speed will be limited to 88 km and ultimately to 6 km in accordance with federal and state requirements.

PURCHASING DIESEL EXHAUST FLUID

DEF, more commonly known as ADBLUE is available from Truck servicing outlets and some automotive parts stores in 10 or 20 litre containers. You can also purchase AD-BLUE from the bowser at any large service stations and truck stops.

FILLING DIESEL EXHAUST FLUID

In the Ford F-series trucks, the DEF filler point is located next to the diesel filler point in-side the fuel flap on the side of the vehicle. The DEF has a blue filler cap. On the Chevrolet or GMC vehicles, the filler neck is located under the bonnet. The blue filler cap can be found at the driver's side rear of the engine bay. When filling with a bottle, you may like to ensure that you have a step, long neck funnel and use only 10 litre containers to make the job as easy as possible. Performax also includes the filling of your DEF at every service which will usually carry a vehicle through to the next service just depending on the usage and driving conditions.

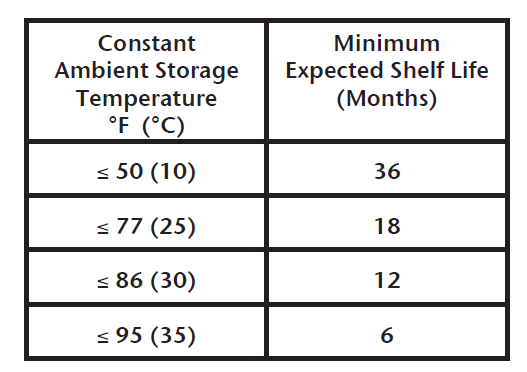

STORING DIESEL EXHAUST FLUID

DEF shelf life is dependent on the conditions under which it is stored. It should be stored out of direct sunlight using the table below as a guide for temperatures and the associated shelf life expectancy. It is not recommended to store DEF as fluid that has exceeded its shelf life or “gone off” will cause problems within the vehicles emission system and cause the vehicle to be thrown into LIMP mode due to the poor quality of fluid. It is usually best to fill your DEF at large truck stops where it is stored in a refrigerated environment and there is a high turnover of large trucks who all use DEF too. This usually ensures you are getting the best quality fluid available Any damage to systems due to the use of incorrect or contaminated DEF is not eligible to be covered under Warranty. If your vehicle is to be stored and not driven for an extended period of time, we suggest that a minimal amount of DEF in the system. When driving the vehicle for the first time fresh DEF should added.

REGENERATION PROCESS (REGEN, BURN)

Regeneration is the process in which accumulated particulate matter is burned off in the DPF. Since diesel soot is comprised of partially combusted hydrocarbons, they can be further combusted, at which point the resulting gases are expelled through the tailpipe and into the atmosphere. In order for regeneration to occur, the exhaust gas temperature must be increased to the point that particulates in the filter combust. This temperature is typically between 550° and 650° C. The three regeneration strategies are passive, active, and manual. Regeneration may also be referred to as “burn”, or just simply “regen”.

Passive regeneration is the naturally occurring regen strategy, requiring input from neither the driver nor engine control module. Passive regeneration occurs when operating conditions, most notably exhaust gas temperature, reach or exceed the minimum range in which regeneration can occur. Passive regen often occurs under relatively high loads at constant speed; long periods of highway driving while towing, for example. Passive regeneration rarely occurs with adequate incidence to completely unload a DPF, although it may reduce the frequency of initiated active regeneration cycles.

Active regeneration is the process by which the control module initiates a regeneration cycle. During this period, fuel is introduced into the exhaust stream where it combusts, raising exhaust gas temperatures such that the burning of particulate matter in the filter is facilitated. The frequency in which active regen is initialized will depend on driving pat-terns - lengthy periods of idling and stop-and-go driving will require more frequent cleaning, while consistent highway driving will reduce DPF loading and negate the need for frequent active regeneration cycles. By nature of injecting raw diesel fuel into the exhaust stream instead of combusting it for means of propulsion, the active regeneration process significantly impacts fuel economy.

Manual or static regeneration is a regen strategy that can be initiated by a technician through the vehicle’s on-board diagnostic system. A manual regeneration is typically initiated in order to repair a malfunction of the system (i.e. Vehicle that failed to regen as needed).

ELECTRONIC ON-BOARD WARNING SYSTEM

There is no guessing involved when it comes to maintaining a correct DEF level with this system. An electronic on-board warning system provides you with numerous warnings in the Driver Information Centre (DIC) to help you maintain adequate DEF levels, alert you if the DEF quality is poor or if there are concerns with the system. See your owner’s manual supplement for a complete description of the electronic on-board warning system and its warning messages.

ADDING DEF TO AN EMPTY OR LOW TANK

Always add at least 4 litres to release the vehicle from any speed limitation. Adding approximately 13 litres of DEF is recommended. Once the system is refilled, the system re-sets itself and a service visit is not required. It may take up to 30 seconds in park or several kilometres of driving to update the DEF level warning.

MAINTAINING DEF QUALITY

The quality of DEF in the tank must be maintained for the vehicle to run correctly. Care should be taken to prevent any contaminants from getting into the fluid. The electronic onboard warning system is designed to automatically monitor DEF quality. If poor-quality fluid is detected, the system will alert the driver. If poor-quality fluid is not replaced within 300 kilometres, the vehicle speed will be limited to 88 km per hour at the next vehicle start. If the system’s warnings continue to be ignored, vehicle speed will ultimately be limited to 8 km per hour.

WARRANTY CONCERNS

System damage caused by using incorrect fluid is not eligible for warranty reimbursement. Care should be taken to avoid introducing any contaminants into the DEF tank or fluid. No modifications should be made to the exhaust system in the area between the engine and the Diesel Particulate Filter (DPF). Modification, tampering or removal of system voids warranty and is subject to hefty fines from the government if detected.